Info & Video

Watch 22oz paper cup forming machine OC22 operation demo video

More vidoe list on youtube: https://www.youtube.com/@Feenot/featured

New tech 22oz paper cup forming machine OC22 speed 80 pcs/min, make 2~16oz hot cold drinks paper cup, one open cam 8 divide, change mold make different cups.

First machine use open cam instead of index gear box, speed rise from 40 to 80 pcs/minute.

Compare with old index gear box cup machine, open cam easy maintenance, long life time.

Change mold tools to make different size cups, max height is 135mm.

It makes paper cup bowl container after the following process: cup fan sucker and feed, cup side wall sealing by ultrasonic, lift the cup wall to main mold, bottom disc punch & insert to cup wall, heating, bottom knurling, cup top rim curling, discharge & rejection, count and packing.

While connect to the paper cup paking machine, make it full automatic, one packing machine online with 4, 6, paper cup bowl container machines.

Widely application: hot drinks coffee tea paper cups, cold colo cola juice milk paper cups, ice cream paper cups, fries chips cups, so on food package solution.

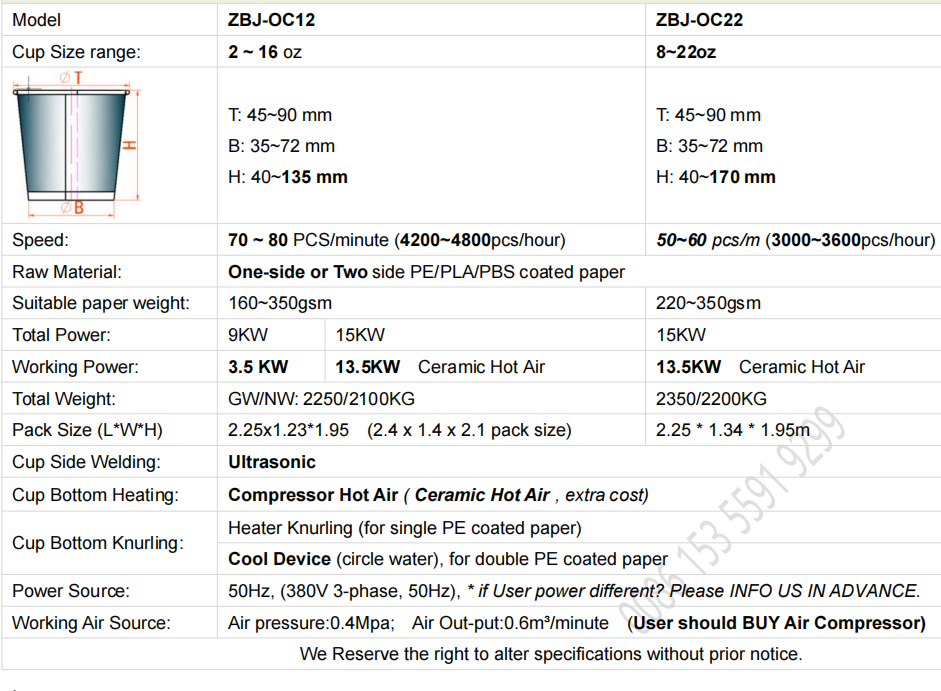

Specification of 22oz paper cup forming machine OC22

- Model: 80S,

- Speed: 80 pcs/minute,

- Cup size: 2~16oz,

- Top: 40~100 mm,

- Bottom: 38~70 mm,

- Height: 35~135 mm,

- Material: 150~320 gsm 1PE & 2PE paper,

- Weight: 2000KG,

- Machine:2200x1340x1900mm,

- Collector: 800 x 700 x 1400mm (against cup size ),

- Total power: 10KW, Working power 5KW,

- Power: 380V 3-Phase 50/60 Hz,

- Need Air (pressure:0.3~0.5Mpa, Output:300~500 L/m),

- Usage: hot drink coffee tea paper cup, cold drink cola juice paper cup,

Advantage of 22oz paper cup forming machine OC22

- HMI + PLC Program computer control, easy operate,

- 11 sensors detect all steps, any fault auto stop, one cup fan cut one bottom disc, no wastage,

- Servo motor control the bottom feed, precision and reliable, no wastage,

- Open Cam(8-divide) drive, compare with index gear box, easy maintenance, stable and reliable, easy replace broken parts.

- Remotecontroller, easy control and adjustment,

- Quality Shaft & gears drive the movement, more stable than chain system,

- Only ONE main turntable, more efficient and reliable.

- Self lubricate(automatic oil lubricate),

- Quality bearing and electronic element, long life,

- Robot straight lift the cup body to main mold.

- Bottom disk straight punched and send to the cup body, less wastage and precision.

- Separately cam control the bottom movement, machine smooth and light,

- Advanced bottom knurling system, reliable and long life,

- Cup side sealing ultrasonic (1PE & 2PE paper),

- Bottom hot air heating , good sealing,

- Working power less, save cost,

- With cup collector/stacker, One worker run 2~3 sets cup machine, save labour,

- Optimize the movement design, frame, parts, machine more light pressure, long life time.

22oz paper cup forming machine OC22

Price of Paper cup forming machine

- How much is Paper cup forming machine cost? Want more information?

- Email: Damond@feenot.com

- QQ: 853962000@qq.com

- Wechat/Whatsapp: 0086 153 5591 9299