ZBJ-OC12 Paper Cup Machine Video

All videos: https://www.youtube.com/user/TheCupmachine/playlists

Video in youtube: ZBJ-OC12 Medium Speed Paper Cup Mkaing Machine Video

Mob/Whatsapp/WeChat: +86 153 55919299

Email: feenot8@gmail.com

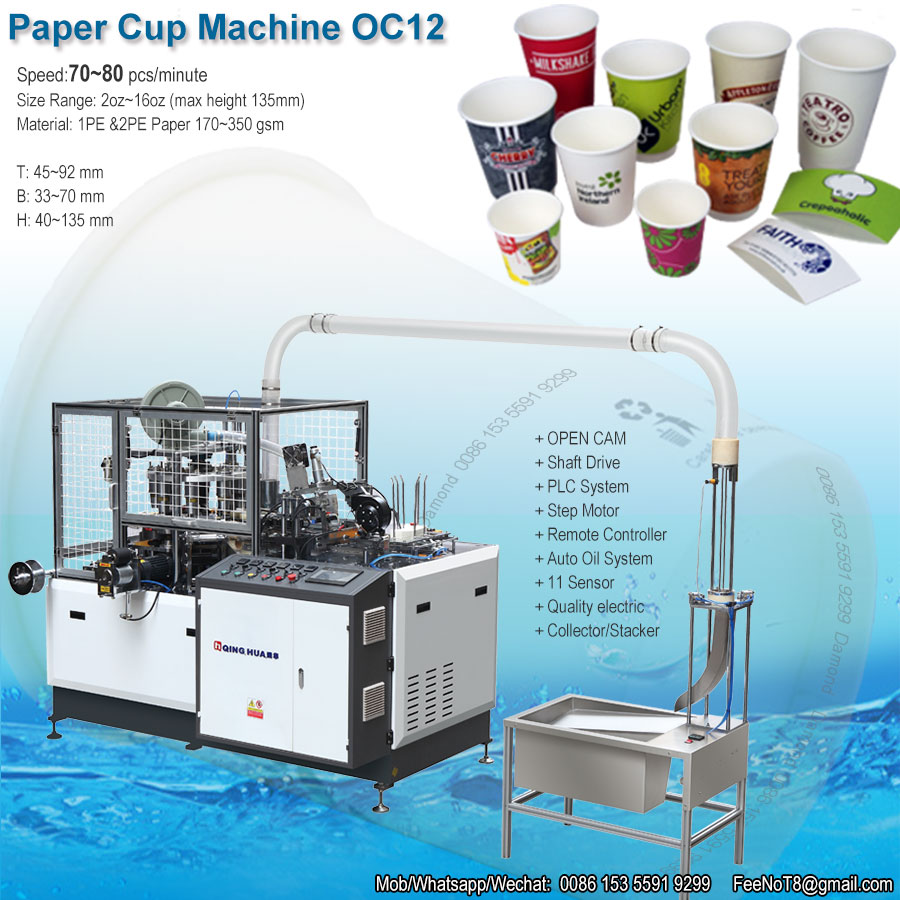

ZBJ-OC12 Paper Cup Machine Brief info

# Speed: 70~80 pcs/minute,

# Cup Size: 2~16 oz

# Material: 150~350 gsm 1PE & 2PE paper

# PLC control, Open Cam + Shaft + Gear drive,

# Servo motor feed bottom,no bottom wastage.

# 11 sensors detect & fault alarm & stop,no wastage,

# Cup side welding: by Ultrasonic,

# Cup bottom heating: by Air compressor Hot-Air,

# Remote controller,

# Quality electric parts(famous brand), Auto oil system

# Working power: around 3.5KW

# Power Source: 380V 3-Phase 50/60 Hz

# Need Air (pressure:0.3~0.5Mpa, Output:0.5 CBM/m)

ZBJ-OC12 Medium Speed Paper Cup Making Machine Picture

ZBJ-OC12 Paper Cup Machine Technician

| Model | ZBJ-OC12 | ZBJ-OC22 | |

| Cup Size range: | 3 ~ 16 oz | 8~22oz | |

| T: 45~90 mm

B: 35~72 mm H: 40~135 mm |

T: 45~90 mm

B: 35~72 mm H: 40~170 mm |

||

| Speed: | 70 ~ 80 PCS/minute | 50~60 pcs/m | |

| Raw Material: | One-side or Two side PE/PLA/PBS coated paper | ||

| Suitable paper weight: | 160~350gsm | 220~350gsm | |

| Total Power: | 9KW | 15KW | 15KW |

| Working Power: | 3.5 KW | 13.5KW Ceramic Hot Air | 13.5KW Ceramic Hot Air |

| Total Weight: | GW/NW: 2600/2500KG | 2700/2600KG | |

| Pack Size (L*W*H) | 2.25×1.23*1.95 (2.4 x 1.4 x 2.1 pack size) | 2.25 * 1.34 * 1.95m | |

| Cup Side Welding: | Ultrasonic | ||

| Cup Bottom Heating: | Compressor Hot Air ( Ceramic Hot Air , extra cost) | ||

| Cup Bottom Knurling: | Heater Knurling (for single PE coated paper) | ||

| Cool Device (circle water), for double PE coated paper | |||

| Power Source: | 50Hz, (380V 3-phase, 50Hz), * if User power different? Please INFO US IN ADVANCE. | ||

| Working Air Source: | Air pressure:0.4Mpa; Air Out-put:0.6m³/minute (User should BUY Air Compressor) | ||

| We Reserve the right to alter specifications without prior notice. | |||

ZBJ-OC12 Paper Cup Machine Other info

- Speed 70~80 cup/minute

- HMI & PLCProgram computer control, easy operate,

- 11 sensorsdetect all steps, any fault auto stop, one cup fan cut one bottom disc, no wastage.

- Servomotor control the bottom feed, precision and reliable, no wastage,

- Open Cam(8-divide) drive, compare with index gear box, easy maintenance, stable and reliable, easy replace broken parts.

- Remotecontroller, easy control and adjustment,

- Quality Shaft & gears drive the movement, more stable than chain system,

- Only ONE main turntable, more efficient and reliable.

- Self lubricate(automatic oil lubricate),

- Quality bearing and electronic element, long life,

- Robot straight lift the cup body to main mold.

- Bottom disk straight punched and send to the cup body, less wastage and precision.

- Separately cam control the bottom movement, machine smooth and light,

- Advanced bottom knurling system, reliable and long life,

- Cup side sealing ultrasonic (1PE & 2PE paper),

- Bottom hot air heating , good sealing,

- Working power less, save cost,

- With cup collector/stacker, One worker run 2~3 sets cup machine, save labour,

- Optimize the movement design, frame, parts, machine more light pressure, long life time.

ZBJ-OC12 Medium Speed Paper Cup Making Machine

| After Sales Service: | ||

| 1 | Warranty: We offer a 12 months warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems (post charges covered by buyer).

All failures/broken caused by improper operation of the buyer and/or normal abrasion are not within the warranty. |

|

| 2 | Spare Parts: Each machine has its standard spare parts. | |

| 3 | Manual, Video, to help operate machine, Questions response within 48 hours (except holiday). | |

| 4 | FREE: The buyer come to learn how to operate machine, how to adjust, how to change parts. It is free.

(buyer should pay for his cost of ticket, hotel, food, etc). |

|

| 5 | The seller agrees to dispatch technician for installation & training, the cost covered by the buyer.

Technician cost includes: round tickets, accommodation (hotel, food), an allowance of USD100 a day. |

|

| 6 | Mechanic overseas Cost include:

1, Mechanic allowance, (for example one machine training 5days, on the way 2days, total 7days, $100*7=$700) 2, Ticket cost, round ticket cost (different country the cost different), 3, Visa cost, some country need visa cost, |

|

20 Feet container load 4sets OC12,

40 Feet container load 8sets OC12