QH-420 Plastic Container Forming Machine Video

QH-420 Plastic Container Forming Machine Decsription:>

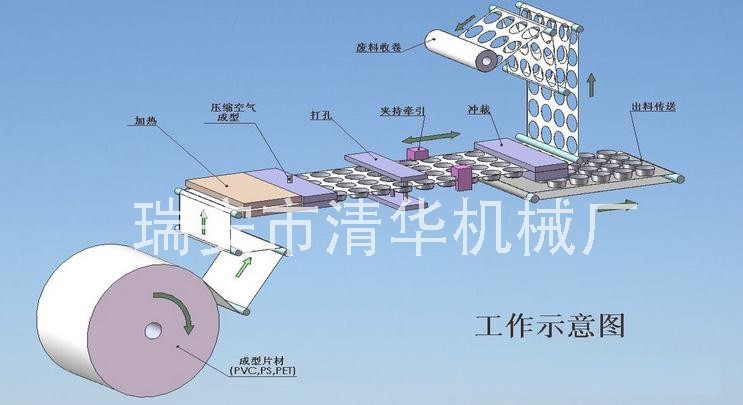

Automatic Lid Forming machine is designed and created by us , with the demand of medical Industry’s ‘GMP’ and food Industry ‘s ‘QS’ Standards.

It’s a new type that combines advantages of several types of main forming machines and adds improvement and innovation .The machine can synchronous complete of production for forming Punching and blanking .

It avoids the cross-contamination of products during the forming artificial punching and artificial blanking. so that the production process of our machine is fully in accordance with ‘GMP’, as well as ‘QS’ requirements .

The Special forming equipment and the special blanking equipment of machine can save electricity , all these can saving the costs of production. It’s widely used in the medicine plastic tray, PET/PS/PVS and other plastic products etc. The machine has beautiful appearance, concession price, convenient operation and humanized manufacturing, and it is deeply favored by users from home and abroad.

QH-420 Plastic Container Forming Machine Main Feature

- Compact structure, Stable movement, Easy operation and maintenance;

- Step-less frequency speed changing, PC electric control panel;

- Move-stroke adjustable, Mold exchangeable;

- Robot clamp-pull feeding, Accurate and reliable Synchronization;

- Applicable Object: plastic tray, cup, container for food, hardware, pharmaceutical, etc.

- Available to make the mold against customer requirement.

Technical Specification

| Name | Plastic Lid Forming Machine | |

| HS.CODE: | 8477800000 | |

| One Line (standard) QH-420 | Three Line (or big size) QH-420S | |

| Max Forming Area: | 410 x 150 mm | 410 x 320 mm |

| Material: | 0.15~0.55mm (HIPS, PET, PS, PVS, PVC, etc) plastic reel film; | |

| Film Width: | Max Reel Width: 430 mm | |

| Punching Speed: | 8~32 beats/minute | 8~30 beats/minute |

| Max Forming Depth: | 30~55 mm | 55mm |

| Move Stroke Rage: | 30~160 mm | |

| Power: | 4.6KW | 6KW |

| Power Source: | 380V 3-phase 50Hz, or other (power different, info us in advance) | |

| Weight: | GW/NW: 1000KG/800KG | 1200KG/1000KG |

| Pack Size: | 2300 x 1000 x 1900 mm | 2450 x100 x 2000 |

| Need Water Source: | Water Pressure: 0.2MPA; Water-Input: 0.3 m³/Hour | |

| Need Air Source: | Air Pressure: 0.5~0.7 MPA;

Air Input: ≥0.2 m³/minute |

Need to buy Air Compressor |

Parts List and Brand

| PARTS NAME+MODEL | QTY | MADE | |

| 1 | Relay+MY2NJ-DC24V+base | 11 | OMRON |

| 2 | Relay+MY2NJ-AC220V+base | 1 | OMRON |

| 3 | AC contactor+ CJX2-1810 | 1 | CHINT |

| 4 | Solid-state Relay SSR-25DA | 2 | AOYI |

| 5 | Computer board | 1 | Local |

| 6 | Temperature controller XMTG3000 | 2 | AISET |

| 7 | Integrated circuit (IC)XMT9081 | 2 | YUYAO made |

| 8 | Button | 2 | YUEQING made |

| 9 | STOP button | 1 | YUEQIONG made |

| 10 | Proximity switch | 6 | WENZHOU made |

| 11 | Pilot relay DZ47-3P-C40 | 1 | HUYU |

| 12 | Pilot relay DZ47-1P-C16 | 2 | HUYU |

| 13 | Pilot relay DZ47-1P-C25 | 1 | HUYU |

| 14 | Pilot relay DZ47-1P-C6 | 1 | HUYU |

| 15 | Power switch S-50-24 | 1 (TAIWAN) | MEAN WELL |

| 16 | Thin cylinder | 3 | KAOGEER |

| 17 | Double rod cylinder | 1 | KAOGEER |

| 18 | Standard cylinder with adjustable stork | 1 | KAOGEER |

| 19 | Thin cylinder with adjustable stroke | 2 | KAOGEER |

| 20 | Positioning cylinder | 2 | KAOGEER |

| 21 | Mini cylinder | 1 | KAOGEER |

| 22 | Electromagnetic Valve | 7 (TAIWAN) | AIRTAC |

| 23 | Main motor 1.5 KW | 1 | LICHAO |

| 24 | Speed reducer 100 type | 1 | JIE PAI |

| 25 | AC Drive 1.5 KW | 1 | INVT |

Remarks:

- Price Given on T/T Payment, Extra USD1000/Shipment For L/C Payment.

- Price Term: FOB Ningbo port, China.

- Payment: T/T( 30% deposit, 70% before delivery) or L/C.

- Lead Time: 30~45 working days at sight the deposit.

- Packaging: Seaworthy Wooden Packing.

- After Sale Service:

Spare parts guarantee for one year,

2. Send technician for installation & training, the cost cover by buyer( round tickets, accommodation, an allowance of USD80 a day).